TECHNICAL RULES

Visiting Cars.

The BG Products Platinum 44k Southern Sprint Car series officials have announced that the series will use the updated rules package that is posted for the 2023 championship season.

If you have any question please contact series officials regarding the 2023 Championship Season.

BODY AND FRAME

- Must be sprint car design: no roadsters or super modified.

- Special racing types only: Aluminum or titanium frames and roll cages are NOT allowed. No bolt-on roll cages.

- Approved Sprint car tail and tank only. Approved fuel bladder mandatory.

- Hood

- All cars must have effective hood latches and must be securely fastened at all times during competition.

- Surface width not to exceed two (2) inches wider than frame. Side risers not to exceed two (2) inches.

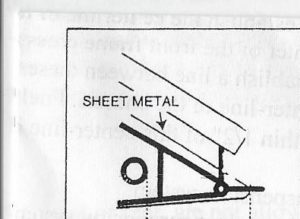

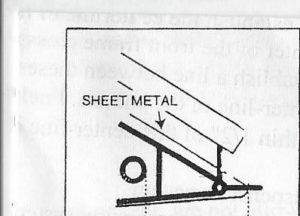

- Front body work sheet metal maximum length as measured from front of front axle not to exceed 28”. NOTE! Front wing including sideboards, is considered part of the front sheet metal.

28″ Maximum

28″ Maximum- Cars will be neatly painted, lettered and presented in a clean professional appearance. Cars not meeting appearance standards may be denied permission to compete.

- Front and Rear Bumpers and Side Nerf Bars are required.

- Front bumpers and nerf bars must not exceed 1” O.D. Nerf bars cannot extend beyond the limits of the wheels/tires on either side and front bumper cannot exceed 28” from front of front axle.

- Rear bumpers must be constructed of 1” minimum O.D. x .065” wall all steel tubing and should be pinned to allow for lifting

- All body panels must be securely attached to the frame.

Seats… FULL Containment seats are REQUIRED

a). All current aluminum seats must be full containment type construction and must adhere to the general

design specifications of SFI 39.2 seat construction standards. Design shall include comprehensive head

surround, shoulder and torso support system, energy impact foam, and removable head foam.

b) Approved carbon fiber seats must have a current valid SFI 39.2 Certification.

c) Up fitting a current seat with bolt on kits will be permitted with a seat manufacturer produced kit and an

acceptable base seat approved by the seat manufacturer. Components must include comprehensive head

surround, shoulder and torso support system, and energy impact foam. It must be installed in accordance

to seat manufacturer instructions. Combining components may not meet SFI 39.2 Certification.

d) Seats must be used as supplied and installed following instructions provided by the seat manufacturer.

e) If the left side head surround is 7 inches or less when measured from the back of the headrest, then a left

side head net meeting the SFI 37.1 must be installed with a quick release latch. A minimum left side head

surround of 4 inches is required.

f) The recommended driver’s seats may be revised from time-to-time with additional approvals and/or other

changes to the approved list.

g) A right side head restraint net and/or support are required. All head restraint nets should be equipped with

quick release mechanisms.

h) The approved nets may be revised from time-to-time with additional approvals and/or other changes to

the approved list. A full containment seat with reinforcement around head and

shoulder restraint sections is MANDATORY.

Wheel Base:

- Wheel base must be a minimum of 84″ up to a maximum of 90” center to center of the hubs.

Drive Line:

- Drivelines must be between the driver’s legs. NO open drivelines permitted.

- No cantilever rear or front ends, (exception of standard dirt car torsion bar setup).

- NO aluminum chassis. NO titanium front or rear axles.

- The engine driveline and center section of the rear axle must be mounted on the chassis centerline at ninety (90) degrees angle to the front and rear axles of the car. The engine must be mounted to the chassis in a vertical position, a maximum of one (1) degree variation will be allowed as measured from the crankshaft centerline. Drivers must not be positioned on or beside the engine. ALL cars must be rear drive.

- Centerline of frame. To establish the centerline of the frame do the following: Establish the center of the front frame cross member and center of rear cross member. Establish a line between these two points, which will be considered the centerline of the chassis. Fuel tank, seat, driveline and engine must be within ½” of this centerline in either direction.

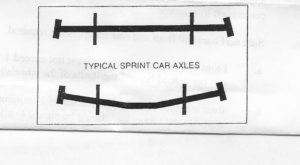

- Suspension system. Independent suspension systems, front or rear will NOT be allowed. Front axle must be single tube with kingpin bosses securely welded at each end as ordered from any sprint car supplier or manufacturer.(Note: may be straight or dropped axle but must remain one piece.

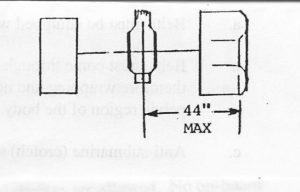

- Maximum amount of offset for right rear wheel. The maximum distance from the centerline of driveline to the outermost portion of the right rear wheel is forty four inches (44”) Note: This measurement is to the outermost part of the right rear wheel or beadlock and not the sidewall of the tire. (see diagram below)

- No electronic traction control devices are allowed. No on-board computers or any other computer adjustable devices are allowed.

- Location of liquid carrying devices. All liquid carry devices must be mounted inside the frame rails and may not be more than 12” from the pre-established centerline of the chassis with the exception to the oil tank. The oil tank may be just to the outside of the chassis and within the nerf bars

- Buckley joints must be enclosed with a full safety blanket or solid steel torque ball housing

- If the swivel rear joint is used a rear extra loop or safety strap must be in place.

ROLL CAGES AND RESTRAINTS

- Main members of the roll bar should be constructed with a minimum of 1 3/8″ O.D.X.095″ wall 4130 chrome-moly tubing. For 1020 Shelby tubing, 1 ½” x .125” wall is recommended.

- Main members of the roll bar must be braced to the front or rear with material having a minimum of the same wall thickness as the main members with at least 7/8″ diameter.

- It is recommended that rear bracing be used.

- It is recommended that bracing be the same diameter as the main members.

- Braces must be attached to the main members at a point within six (6) inches from the top of the rear transverse member as close to the top as possible.

- Roll Cage must extend two (2) inches above the top of driver’s helmet when sitting in an upright position. Roll cage padding is recommended.

- Seat Belts must be a minimum of two (2) inches wide with a minimal tensile strength of 8,000 pounds loop test. Worn appearing belts can be rejected by series officials or technical inspector. Belts must be no older than three (3) years.

- Belts must be equipped with a metal quick release buckle

- Belts must come through the seat at the bottom of each side, therefore wrapping and holding the greatest possible area of the pelvic region of the body.

- Anti-submarine (crotch) seat belts are required.

- Shoulder harness must be a minimum of double over the shoulder style or any approved racing harness. Shoulder harness must be a minimum of two (2) inches wide with a minimum tensile strength of 3,000 lbs. Belts must not be older than three (3) years.

- The driver restraint assembly must conform to the SFI 16.1 specifications and be no older than two years of manufacturers date on harness. 3” wide lap belts and either 2”or 3” wide shoulder harness will be allowed.

- Cage nets are required for safety on the right side of car unless the car has a full containment seat in which a cage net will not be required.

- ENGINES

-

A. Engine Specifications1. CID Engine Specification and Relation to Total Minimum Weight2.1.1 Must be piston driven, cam in block, production based engine. No super chargers, turbos or nitrous oxide allowed.2.1.2 Minimum Weights per engine1550 lb minimum 360 CID cast iron block with 23* +/- 2* heads (open injection)1550 lb minimum ASCS 360 Ford or Mopar 2 3/16 restricted injection1575 lb minimum 360 CID Aluminum block with 23* +/- 2* heads (2 3/16” restricted injection)1600 lb minimum 360 CID Aluminum or Steel block less than 23* +/- 2* heads (2” restricted injection)1600 lb minimum 360 CID Ford or Mopar unlimited head (2.100” restricted injection)1600 lb minimum 410 CID Aluminum or Steel (1 7/8” restricted injection)2.1.2 1 1/2” of total restriction on all combinations2.1.3 Engines may be pumped for size and cars may be weighed for compliance at any time at the discretion of the Race Director. Engines may be sealed by a technical official.2.1.4 After being pumped for size to eliminate the need for pumping at subsequent2.2 Blocks -Must be American or Canadian Made. Big Blocks not approved2.3 Weights and Injector stacks may be adjusted to equalize competition.

3. Any American manufactured block for automobiles or trucks with a stock camshaft location and had (8) cylinders.

IGNITION

- Ignition is optional. Must have a shut off switch within easy reach of the driver or the outside rescue crew in case of an accident.

- NO crank sensored ignition is permitted.

- NO SUPERCHARGERS OR TURBOCHARGEERS ALLOWED.

HEADS

Only stock appearing heads for the engine with two (2) valve and one spark plug per cylinder allowed. Any aftermarket of original design in aluminum or steel may be used. This rule pertains to small block Chevy: however, any engine may be used after approval of the Southern Sprintcar Shootout Series. Spread port exhaust will be allowed.

TITANIUM

NO titanium in engine excluding valves and the valve retainers. Oil pan inspection plug of at least 1” N.P.T. is recommended so as to be able to check crankshaft material. If you do not have an inspection plug, you will have to pull the pan if inspection is required.

Fuel and Air Systems

- Fuel must be methanol only with no additives other than top lube. No nitrous oxide.

- Car must have fuel shut-off valve that is clearly indicates “OFF”.

- All fuel is subject to testing at any time. Any fuel that does not conform to the Southern Sprintcar Shootout Series standards, as administered at the track, will be considered illegal.

- Any device(s) or material(s) that artificially reduces the temperature of the fuel is prohibited.

- As a result of manufacturing processes, some injector stacks may be slightly larger. A tolerance of .005” will be permitted on all stacks.

- Reducing sleeves a minimum of three(3) inches in length must be installed in the stacks above the butterflies.

- On Chevy engines, the injectors must be no larger than 2-3/16” plus .005” inside diameter of the injector stacks. All Fords are not to exceed 2.100” plus .005” inside diameter.

- No relief boles or grooves may be exposed above or below the butterflies on the injectors.

- Fuel Pumps – No glass fuel pumps or filters allowed.

WHEELS AND TIRES

- Any wheel designed for racing is permitted.

- Bead locks are optional.

- Maximum width of right rear wheel is 18 inches, left rear is 15 inches, fronts 12 inches.

- All tires must be on the Southern Sprintcar Shootout Series approved tire listing. All tires must be purchased thru the approved Southern Sprint Car Series dealer. NO OUTSIDE TIRES WILL BE APPROVED.

- Left Front: TBA American Racer

- Right Front: TBA American Racer

- Left Rear: TBA American Racer

- Right Rear: TBA America Racer

- A minimum durometer reading will be in effect as stipulated by American Racer Tires Technical Developers.

- If at any time the Southern Sprintcar Shootout Series makes a change in the tire rule, a rules update will be provided to all participants.

- Illegal tires will result in disqualification for that event. NO TIRE PREP ALLOWED.

- All cars transferring directly to the A-Main MUST use the same right rear tire in the Heat/Time Trials.

- Teams that run the consolation race may change the RR tire to start the race, but ALL transfer cars must run original RR in the A-Main that was used for the heat race or Time Trials.

- Recommended to have a safety pin or wire tied in axle tube outside wheel nut.

F.WINGS

- TOP WING

- Use of the top wing shall be mandatory for all races. (NON Wing races will be run)

- Top wing may not exceed twenty-five (25) square feet. 2” wicker bill allowed.

- Side boards maximum size, 75 inches long and 30 inches tall.

- The deepest point allowed in the top surface of the wing will be 2 .5 inches

- Center foil shall be fully sheathed in aluminum. Vent holes are strictly prohibited.

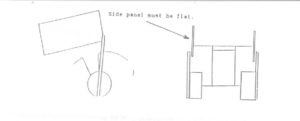

- Wing placement shall not exceed the outer edge of the rear wheels. (see diagram below)

- As shown in the above drawing for wing side panels, both side panels must be flat.

- Hydraulic wing sliders allowed (front to back movement only).

- No side foils, rudders or panels are to extend beyond roll cage on any side. No wedges or foils underneath the cars are allowed. NO louvers allowed in the floor pan.

- NOSE WINGS

- Allowed but not mandatory.

- Maximum of six (6) square feet with 12 inches by 28” inches on both side boards. One (1) inch wickerbill is allowed

- Leading edge must be mounted forward of the front axle centerline and aft of front bumper.

- Wing to be mounted above nose of car.(see diagram below)

DRIVESHAFTS

- Safety loops or restraints are mandatory and must be approved.

STEERING

- Steering system must be engineered and assembled in accordance with sound engineering principles.

- Approved removable type steering wheel disconnect only. No plastic parts allowed.

- Any welding on steering mechanism must be approved by inspector.

BRAKES

- Car must have operable front and rear brakes .

- No Carbon Fiber or Titanium front rotors.

UNDERPAN

All cars are required to have a floorboard or underpan under the cockpit area and engine compartment extending from the radiator to the rear motor plate. (exception: Visiting legal dirt cars)

DASH

Effective fire wall must be installed between engine compartment and cockpit.

MUFFLERS

Headers must merge into a collector. All cars must meet decibel requirements of the individual speedways. Some tracks may have a particular muffler requirement. Participating race teams should always check with each track if requirements are unknown.

SHOCKS

- Cockpit adjustable shocks are not allowed. NO weight jackers inside driver cockpit.

SAFETY

- General: “ALL SAFETY ITEMS MUST MEET CURRENT SFI RATINGS”

A.) Each competitor is the solely responsible of for the effectiveness and proper installation, per the manufacturer’s specifications, of personal safety equipment and determining it to be adequate for competition at every event. Each competitor is expected to investigate and educate themselves for continuing improvement regarding their own personal safety equipment.

2..Seats… FULL Containment seats are REQUIRED

a). All current aluminum seats must be full containment type construction and must adhere to the general

design specifications of SFI 39.2 seat construction standards. Design shall include comprehensive head

surround, shoulder and torso support system, energy impact foam, and removable head foam.

b) Approved carbon fiber seats must have a current valid SFI 39.2 Certification.

c) Up fitting a current seat with bolt on kits will be permitted with a seat manufacturer produced kit and an

acceptable base seat approved by the seat manufacturer. Components must include comprehensive head

surround, shoulder and torso support system, and energy impact foam. It must be installed in accordance

to seat manufacturer instructions. Combining components may not meet SFI 39.2 Certification.

d) Seats must be used as supplied and installed following instructions provided by the seat manufacturer.

e) If the left side head surround is 7 inches or less when measured from the back of the headrest, then a left

side head net meeting the SFI 37.1 must be installed with a quick release latch. A minimum left side head

surround of 4 inches is required.

f) The recommended driver’s seats may be revised from time-to-time with additional approvals and/or other

changes to the approved list.

g) A right side head restraint net and/or support are required. All head restraint nets should be equipped with

quick release mechanisms.

h) The approved nets may be revised from time-to-time with additional approvals and/or other changes to

the approved list. A full containment seat with reinforcement around head and

shoulder restraint sections is MANDATORY.

3 Protective Clothing

A.) All drivers will be required to wear a fire resistant driving uniform meeting minimum of the SFI 3.2A/5 specification and display a valid SFI 3.2A/5 label.

B.) All drivers should wear fire resistant accessories including but not limited to; head sock, under garments, shoes, and socks.

C.) All drivers will be required to wear fire resistant gloves. Shoes and gloves will be required to meet minimum of the SFI 3.3 specifications and display a valid SFI 3.3 label.

4. Helmets…Head and neck restraints must be used. Device must be approved by Southern Sprint Car Series Officials.

A.) All drivers will be required to wear a full-face helmet with a minimum safety rating of FIA 8860-2004, FIA 8860-2010, Snell SA 2005, Snell SA 2010, Snell SAH 2010 and/or a valid SFI 31.1/2005 label.

B.) It is strongly recommended that helmets should have the Eject ™ helmet removal system installed as per the manufacturer’s instructions.

C.) Safety equipment must be worn at all times

D.) Arm restraints are required and must be connected and used as instructed by the manufacturer.

Other RECOMMENDED

A.) No sharp and/or protruding edges in and around the cockpit.

B.) Windshield screens are strongly recommended.

C.) A clearly marked electrical engine shut off switch within the reach of the driver.

D.) A clearly marked fuel shut off valve within reach of the driver.

E.) Only SFI flame retardant seat, roll bar, knee and steering pads and/or padding should be utilized.

F.) A drive line containment system; either a steel torque ball housing made of a minimum .120 wall thickness magnetic steel attached to the firewall with steel and/or titanium bolts and/or a torque ball u-joint containment blanket is mandatory to shield revolving parts within the cockpit.

G.) All teams should have an easily accessible 2.5 gallon FFF fire extinguisher or its equivalent at the back of the team’s transporter.

- All drivers must wear approved helmets securely fastened.

- All drivers are required to wear uniforms, including driver’s suits, underwear, gloves, approved racing shoes and socks, covering the body made of fire resistant material.

- Arm restraints are mandatory.

- Fireproof head socks, knee guards, and some type of neck/head device are highly recommended.

MIRRORS

Mirrors are NOT allowed.

WEIGHT RULE

- Minimum weight requirement

-

Minimum Weights per engine1550 lb minimum 360 CID cast iron block with 23* +/- 2* heads (open injection)1550 lb minimum ASCS 360 Ford or Mopar 2 3/16 restricted injection1575 lb minimum 360 CID Aluminum block with 23* +/- 2* heads (2 3/16” restricted injection)1600 lb minimum 360 CID Aluminum or Steel block less than 23* +/- 2* heads (2” restricted injection)1600 lb minimum 360 CID Ford or Mopar unlimited head (2.100” restricted injection)1600 lb minimum 410 CID Aluminum or Steel (1 7/8” restricted injection)

- Added weight must be bolted on, safely and securely, to and within the confines of the frame rails, between the axles and no higher than 12” above the bottom of the lower frame rails.

- Any bolt on weight must be painted white and the car number must be on the weight.

- The weight must be securely attached and must remain in place during a race. It must not be moved or removed during a red flag situation.

- Series officials reserve the right to weigh any car at any time during an event.

- The top 5 finishers in the feature will proceed directly to the scales to be weighted immediately after the event has been completed.

- Crew members will remain clear of their cars until the weight inspection has been completed.

PENALTIES – The penalty for not making weight, there is NO LEEWAY

a. Will be credited with last place points and money in the event you are competing in.

DISQUALIFICATIONS / PENALITY LIST – DO NOT GO TO YOUR PIT AREA FIRST!

- Failure to report directly to the scales (locations of the scales will be announced at the drivers meeting)

- Loss of any bolt-on weight during competition

- Weight mounting procedure does not meet our specifications.

- Rough Driving

- Unsportsmanlike Conduct

- The above infractions are a basic guideline and are not limited to the above.

- Resulting penalties may be: (A): Place as the last car on the lead lap or (B) depending on severity of infaction, revieve last place points and money.

CHECKING YOUR WEIGHT

- Chunk weight up to 20 lbs (2-3/8” grade 8 bolts with nylock nuts or safety wire)

- Chunk weight up to 50 lbs (2-1/2” grade 8 bolts with nylock nuts or safety wire)

- Plate steel up to 30 lbs (4-5/16” grade 8 bolts with nylock nuts or safety wire)

- Plate steel up to 60 lbs (4-3/8” grade 8 bolts with nylock nuts or safety wire)